Pentek 155358, DGD-5005 Compatible Dual Gradient Polypropylene Sediment

Pentek 155358, DGD-5005 Compatible Dual Gradient Polypropylene Sediment

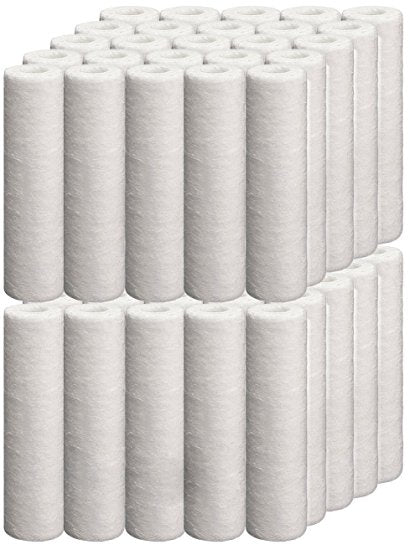

This spun polypropylene filter cartridge reduces sand, silt, scale, and rust particles in residential, commercial, and municipal drinking water. It has two separate gradient layers for higher particle reduction efficiency and dirt-loading capacity than standard spun or string-wound cartridges. The nominal filtration rating of the pre-filter layer is 50 microns, and the rating of the post-filter layer is 5 microns. The filter is made of spun polypropylene fibers for resistance to chemicals and bacteria. It has an initial pressure drop of less than 1 pound per square inch (psi) at a flow rate of 20 gallons per minute (gpm), and operates over a temperature range of 40 to 145 degrees F (4.4 to 62.8 degrees C). This spun polypropylene filter cartridge meets National Sanitation Foundation/American National Standards Institute (NSF/ANSI) standard 42 for quality assurance, and is used for treatment of residential, commercial, and municipal drinking water.

Specifications

| Nominal filtration rating (pre-filter) | 50 microns |

| Nominal filtration rating (post-filter) | 5 microns |

| Initial pressure drop at 20 gpm | <1 psi |

| Temperature range | 40 to 145 degrees F (4.4 to 62.8 degrees C) |

| Maximum dimensions (H x W) |

|

| Materials certification | NSF/ANSI standard 42 |

The nominal filtration rating is for a particle removal efficiency of 85%.

H is height, the vertical distance from lowest to highest point; W is width, the horizontal distance from left to right; D is depth, the horizontal distance from front to back.

Water filters remove undesirable particles, chemicals, and microorganisms from water by means of a semipermeable barrier, adsorption, or biological processes. They are made of densely packed synthetic or natural fibers that trap suspended particles, materials that block microbes or adsorb unwanted chemicals, or substances that cause a chemical change, such as acid neutralization. For most residential, commercial, and industrial applications, water filters are manufactured in the form of replaceable cartridges that fit inside permanent housings. Filtration systems typically consist of a series of two or more types of filters, each designed to remove different contaminants. The performance of filters is measured by the minimum particle size that is blocked, the percentage of particles or microorganisms that are removed, the downstream concentration of unwanted chemicals, the maximum flow rate, and the amount of water that can be filtered before the filter must be replaced. Water filters are used in a wide range of applications, including drinking water purification, swimming pools, industrial processes, and irrigation, among others.